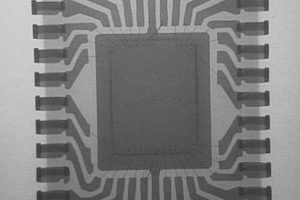

X-ray Analysis of a Transducer for the Defense/Military Industry

At Electro Product Management, Inc., we have the ability to provide conclusive testing and analysis that allows customers to correct any existing quality issues at their root. A customer in the defense industry contacted us regarding issues they had been experiencing with a transducer that is used inside of a hybrid device. The customer suspected that the quality issue was stemming from production at the manufacturer, but they didn’t have the ability to confirm their suspicions. We were able to use X-ray equipment to verify that the problem was being caused by quality issues at the manufacturer.

Our ability to provide X-ray analysis in-house allows us to diagnose a range of issues that would otherwise go undetected. This nondestructive method of testing is able to provide insight into layers of electronics construction that would be lost in destructive testing, and since the device is left intact, X-ray inspection is often much more cost effective for expensive parts or large sample sizes than destructive testing and analysis. The customer entrusted us with this project because this challenge called for an extensive analysis to verify the root of the quality issue, requiring a strong depth of knowledge regarding microelectronics and related inspection methods.

We are adept at solving unique testing challenges and have a wealth of experience in designing, engineering, and fabricating custom electronics procedures and test fixtures. Our team can customize inspection methods based on the specific application to ensure that customer’s products meet the most stringent quality standards. For additional information about this custom electronics X-ray inspection project, see the table below, or contact us directly.